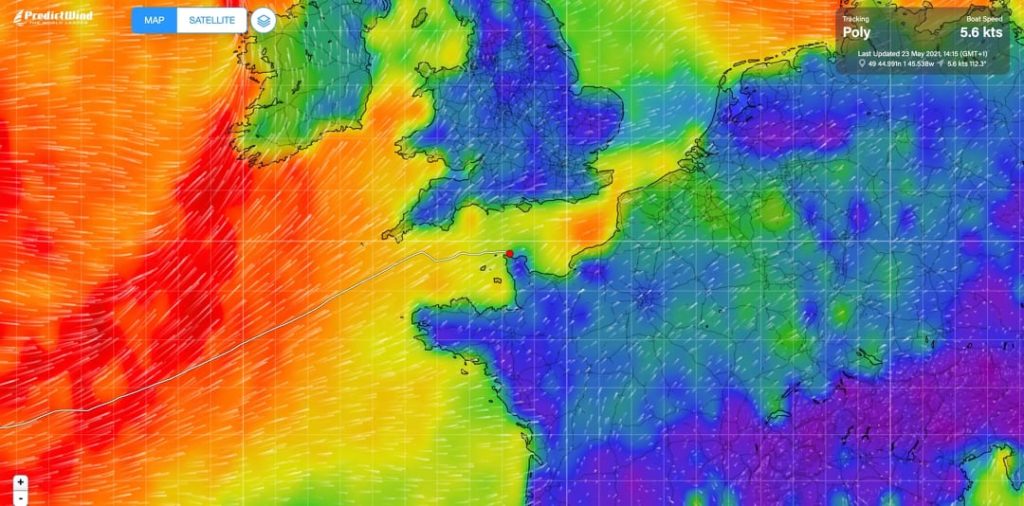

Broken steering! Yep. One of my worst nightmares on a boat with one rudder. There was a good reason why we invested into the completely newly designed and built rudder and all the associated mechanism including totally oversized hydraulics to drive it 6 years ago. And truly for 6 years and 50 thousand miles it has performed flawlessly. As usual I have a lot of luck in a potentially very dangerous situation. It all happened 20 miles south of the English shores at the mouth of the English Channel with fair weather, wind pushing us in the desired direction even while adrift, and forecast indicating more favorable conditions. We were also 10 miles away from the nearest shipping lanes, which are by the way one of the most traffic congested in the World. I am grateful to the universe for it not happening few days earlier in the midst of racing withe monster low, when 50 miles difference could have made things very dangerous specially if we were drifting sideways, or with our back fully exposed to the breaking 5-6 meters waves to the waves. Few days later while in the tight Danish Straight with the wind abeam it could have proved disastrous as well. So here we are speeding happily in one piece after the monster low passage thanks to which we made some really good gains and were hoping for end of May in Poland. We then decide to add the mainsail as the wind is lightening up. So we roll the genoa and go adrift to recalibrate the autopilot and rudder indicator readings as it has been giving us some weird situations in the last few days. We calibrate 3 times eventually to a successful outcome verifying visually the rudder arm and hydraulic piston positions as we go along. Everything looks good finally and we start the engine to test and go upwind to raise the main, but then the boat goes on its on merry way in the direction opposite to what I am doing with the steering wheel. Full wheel to starboard, full to port, no effect on the heading. We stop. I start with looking for the fault with possible air in the hydraulics. So I first make sure there is enough hydraulic fluid in the system, then we bleed the system with no apparent problems found. The rudder arm is still moving in sync with the steering wheel.

So I am a bit dumbfounded. So I finally have moment of enlightenment and look for the simplest confirmation of all at the source. I stick my head down from the central transom to find the rudder blade dancing with the waves happily and turning freely seemingly unrestricted around the rudder post. I was prepared for a lot of scenarios having only one rudder, but not for this one. I never thought you could twist off the blade from its post and still keep the blade. That’s the very good news. We sit down and think for a while and we come up with a bit of a crazy plan to build a new steering system on ropes and blocks.

The key part of the plan is tying the the hitch (or a double loop) knot around the entire blade with the ropes sticking out to the sides of the trailing edge and leading them through a system of blocks to our existing steering wheel.So first Peter takes a dive, I am assisting from the transom, but he’s got so much buoyancy that he cant’s dive under the rudder, while the waves are throwing him back and forth making it impossible to use the boat hook to hook the loop at the bottom of the rudder blade. After about an hour we take a break and I conclude that we either get it done or we gonne have to call for help. Otherwise we gonna be drifting uncontrollably at night across world’s most frequented shipping lanes and eventually towards the rocky shores of Normandy. Not my favorite scenario.

I dispatch few emails to start looking for assistance. Then I done the wet heavy wetsuit and put on 8 kg of lead on my weight belt so that this thick neoprene does not keep me so buoyant as to prevent diving on the rudder. I jump in with the loops perfectly aligned by Keeler’s (Pawel’s) electrical tape bands, I wait for a moment for the next wave to spring the back of the boat up i jump underneath and push hard against the bottom to submerge. I manage to reach the bottom edge of the rudder with my left hand and pull myself deeper. From this position putting on the loops is a mere formality I place them about halfway down the blade, resurface and scream to pull on the lines so that the loop tightens. It does perfectly, despite my momentary concern that I placed it backwards. We then tie the ends of the ropes from each side that are already lead through the blocks and steering wheel. Tighten the block and everything is ready to try. We first move the rudder while I am still in the water to make sure everything is correct. Than I jump out we start the engine and … IT IS WORKING!!! We are on the way. Under control. The steering is a bit funny not the least because we wound the rope around the steering wheel in reverse, so in order to go left you have to turn the wheel right. But it is working. We are now 15 miles from Cherbourg where I decided to head for repairs.

In 2014 we stopped here when our propeller twisted off. As it turned out the marina has big ramp where we can float in at high water and make repairs at low water while the boat is standing stable on its four legs. It’s an awesome shortcut when you think of a 120 Ton crane as an alternative. Quick and cheap one. Keep your fingers crossed.

Bartek

We invite you to the next updates straight from the Ocean.

If you feel that our creativity is valuable to you and brings joy to your everyday life, join us and support our activities. We will be very grateful for your support.

We invite you to join our group only for Patrons who, among others, can follow Bartek online in our closed LOVE BOAT group on Facebook:

https://www.facebook.com/groups/2314256138815617

To join us, we invite you for more information here:

https://sailoceans.com/support-our-creation/

Stay safe and fair winds,